LCC Liquid Coil Coating Line

MACHINERY PLANT DIVISION

SMF FINISHING LINES

Liquid Coil Coating Line plant cod. FL01LP_24

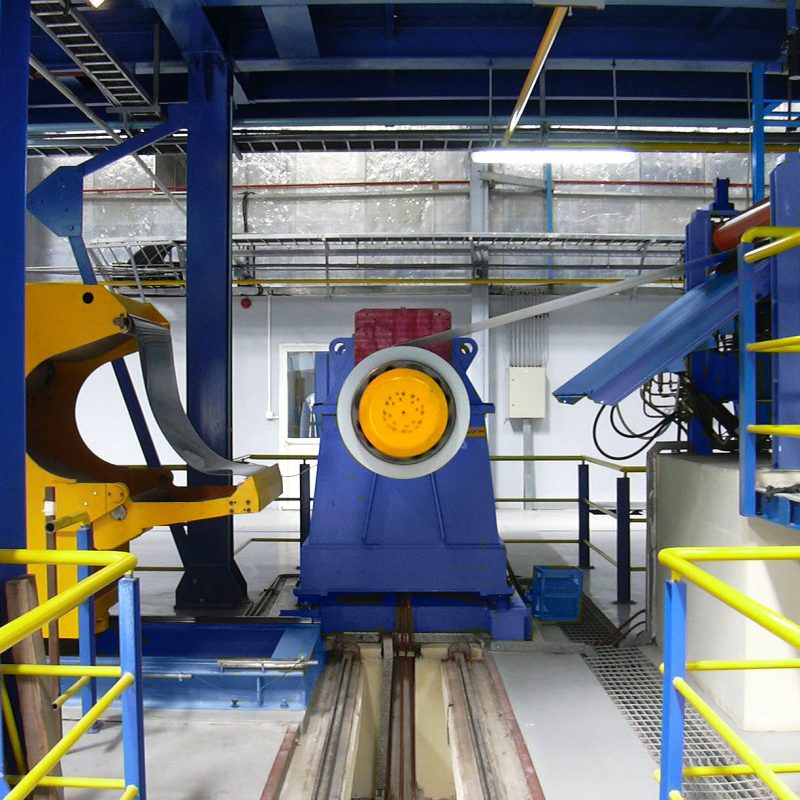

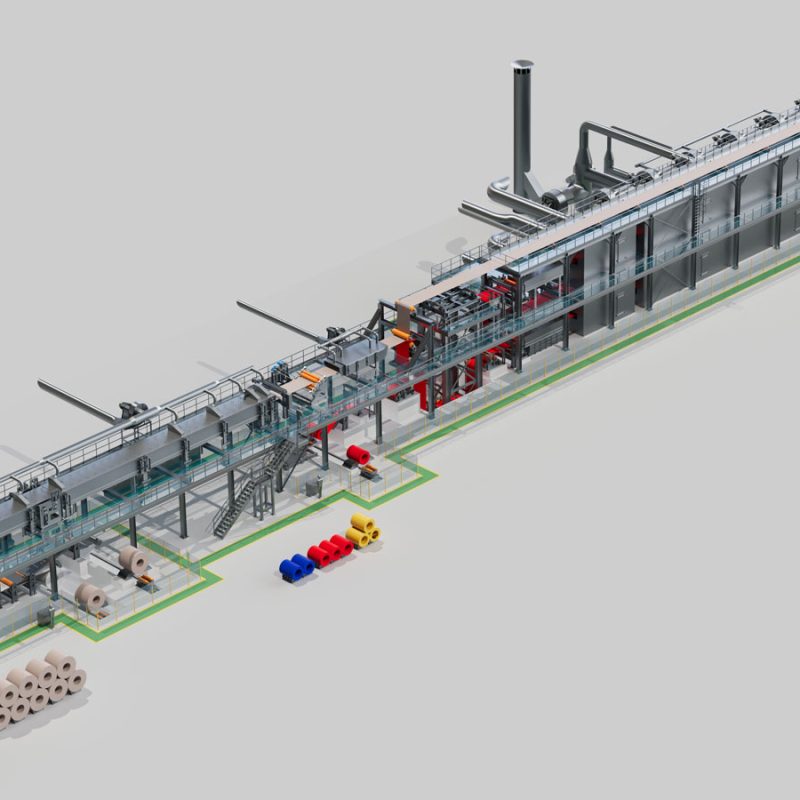

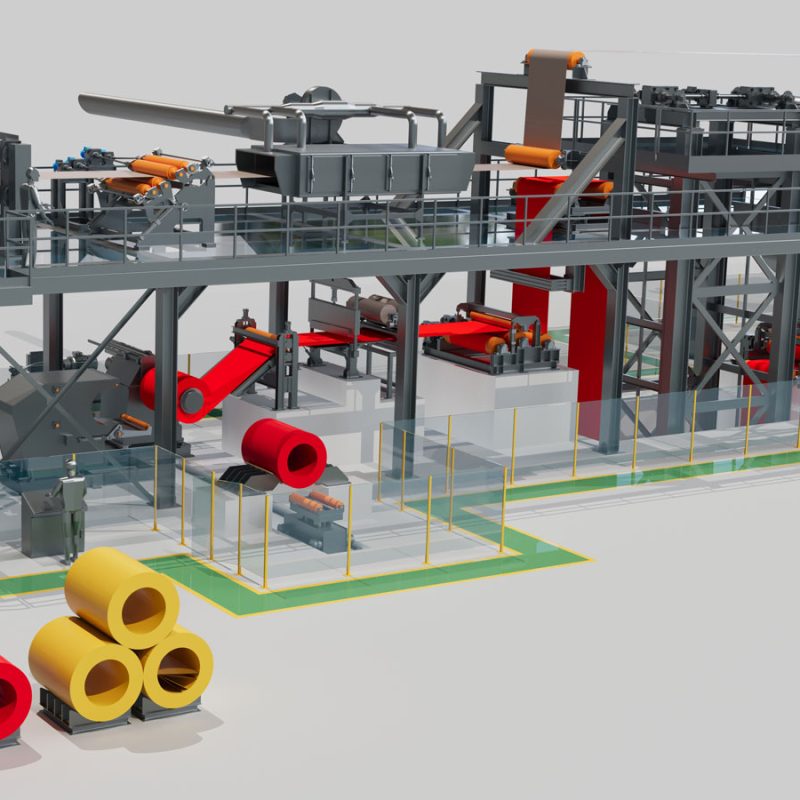

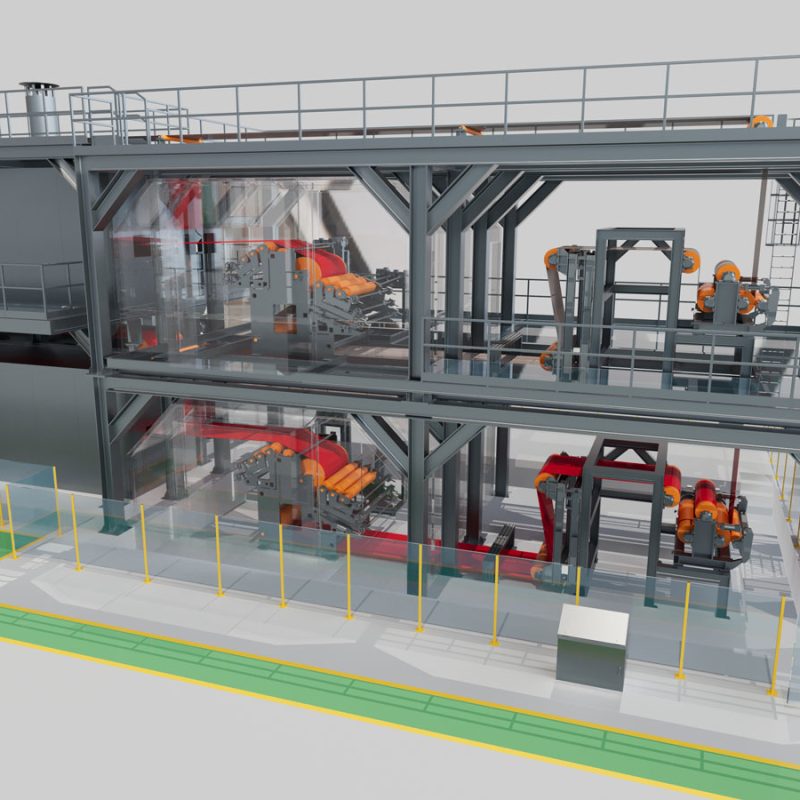

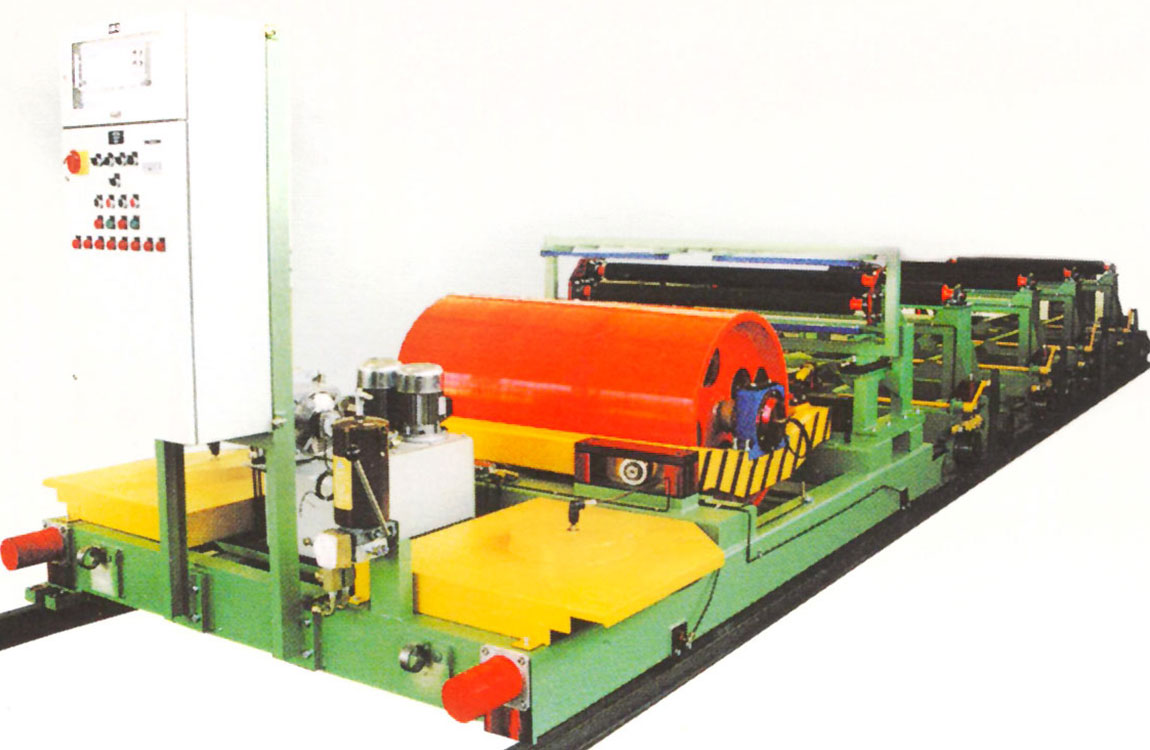

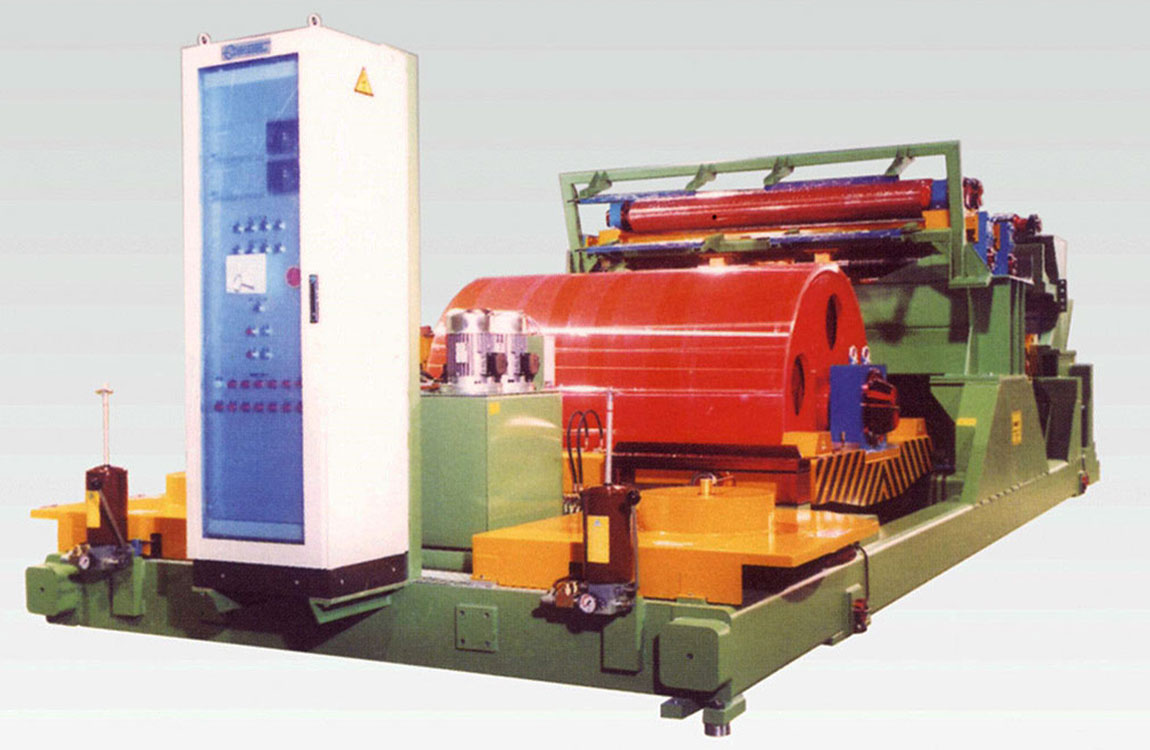

LCC Liquid Coil coating line it is composed of a series of technological areas: entry area, degreasing and cleaning area for the surface preparation of the strips, paint application area, paint polymerization and cooling area and exit area. The described area identify the plant layout.

In general, the line is based on a controlled strip drive system, on a process system and an electro-instrumental architecture necessary for the continuous management of the automation of the plant.

The system allows the application of paints either on one side (top) or on both sides (top and back) of the processed belts.

The strip drive system includes:

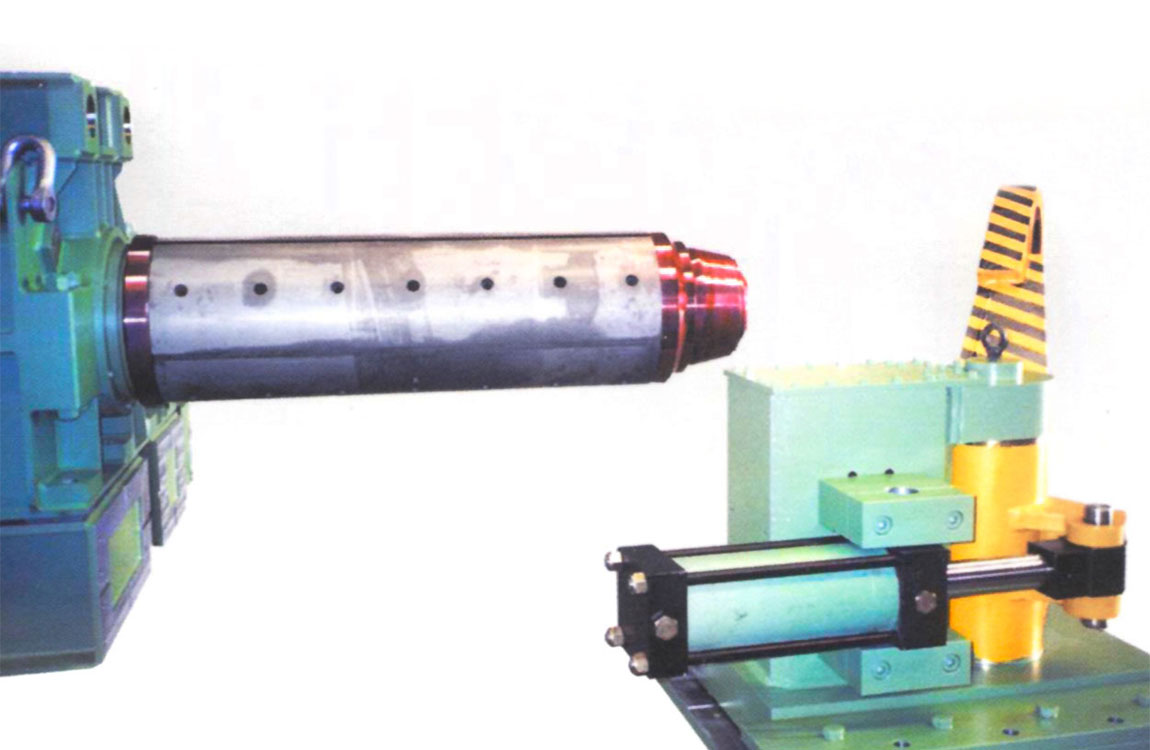

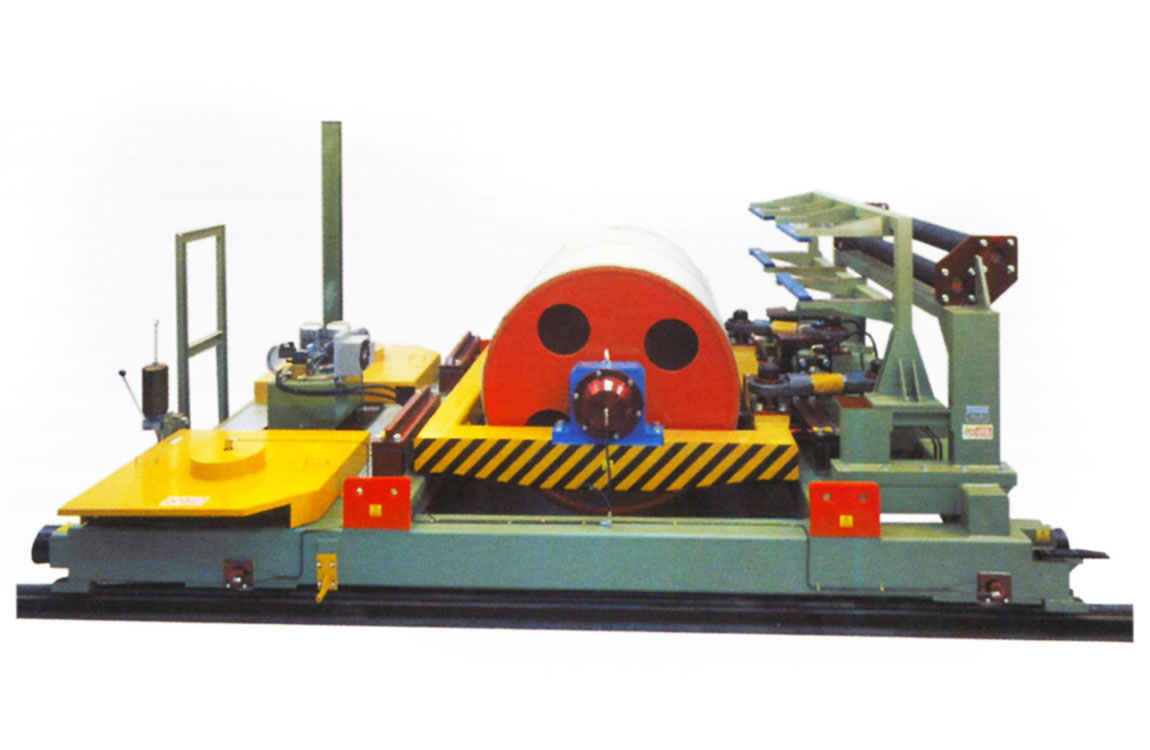

- Groups for coil loading and unloading;

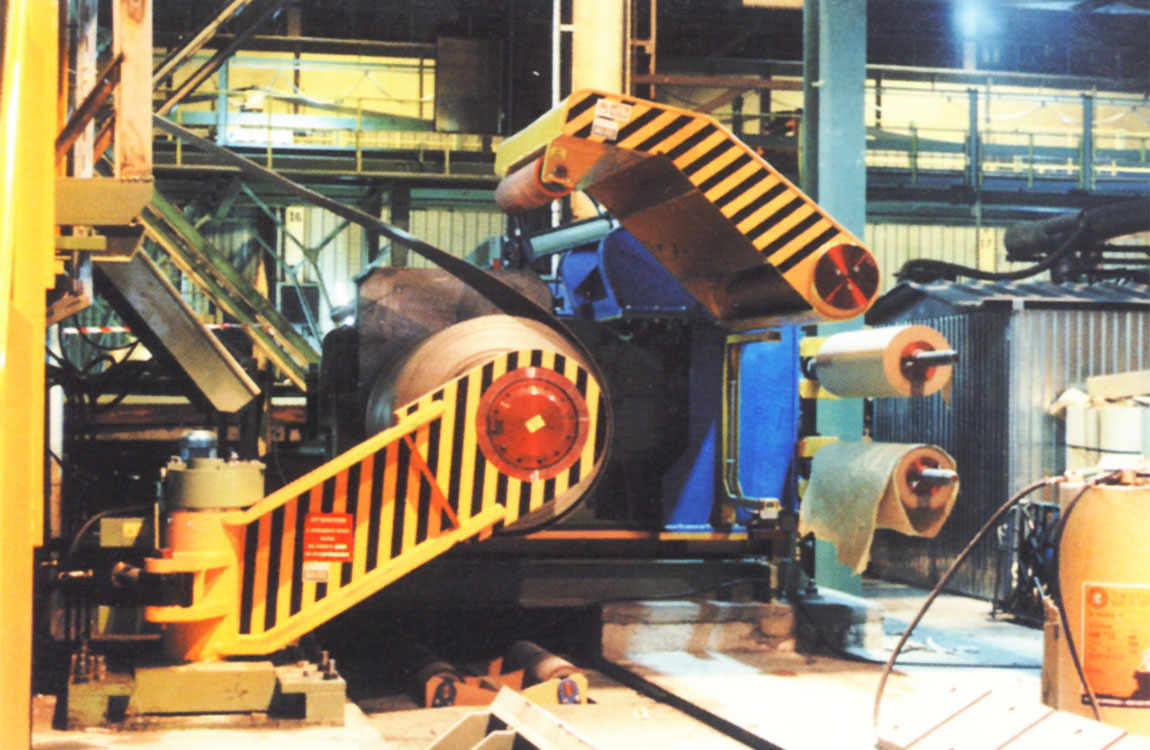

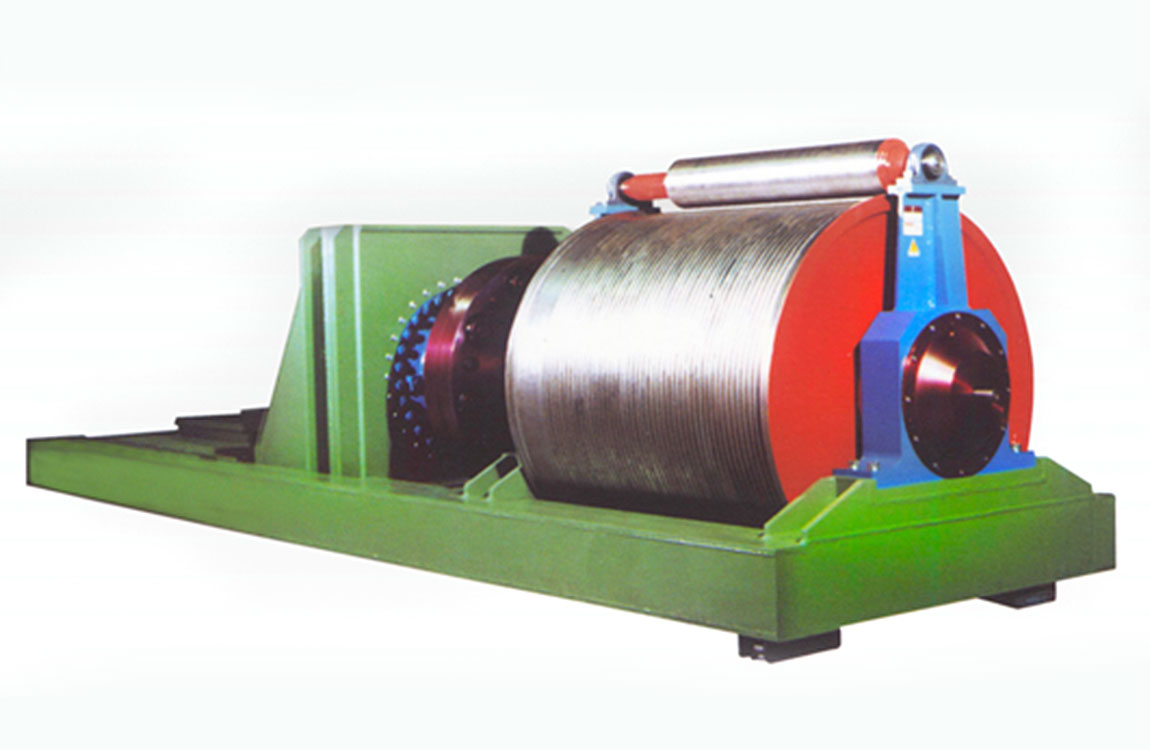

- Groups for strip decoiling and recoiling;

- Groups for strip centering;

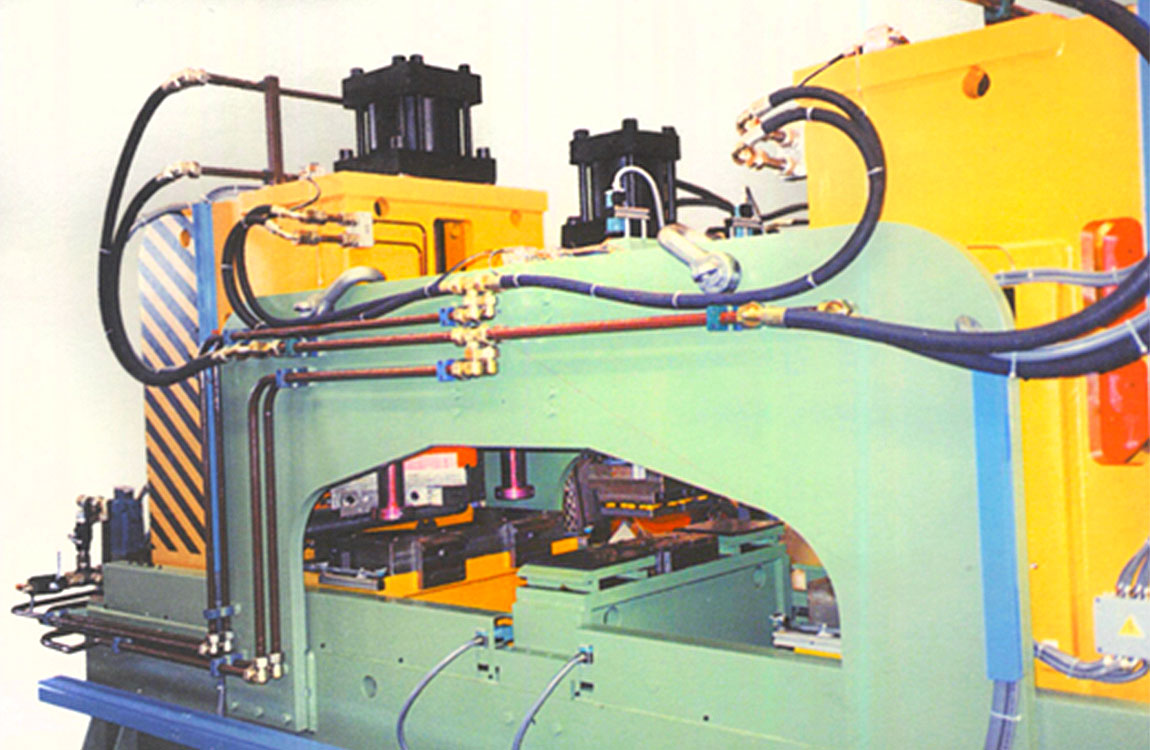

- Groups for strip end cutting and junction;

- Groups of strip tensioning bridle;

- Groups of strip accumulation;

- Groups for spools insertion;

- Groups for plastic film application.

The process system includes:

- Possible strip levelling;

- Strip surface cleaning unit, generally by spray, with relative drying;

- Immersion, spray, roller or “soft rain” strip conversion unit with relative drying;

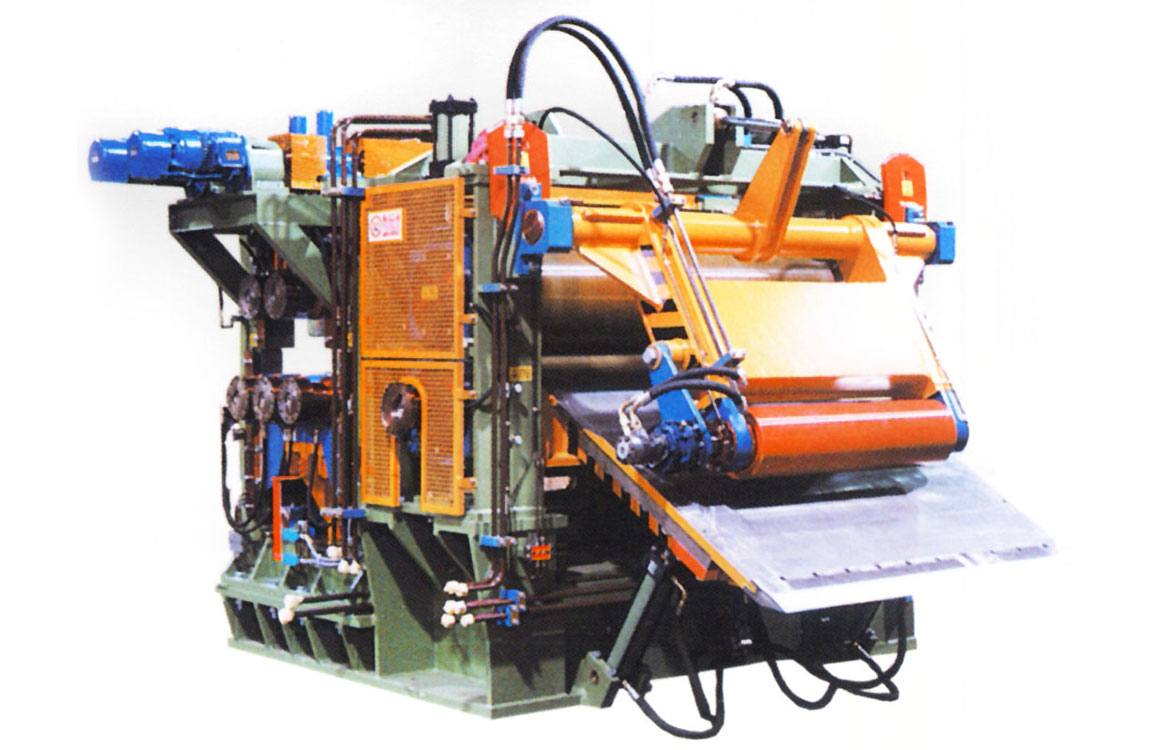

- One or more rolls coating machines for liquid paints application;

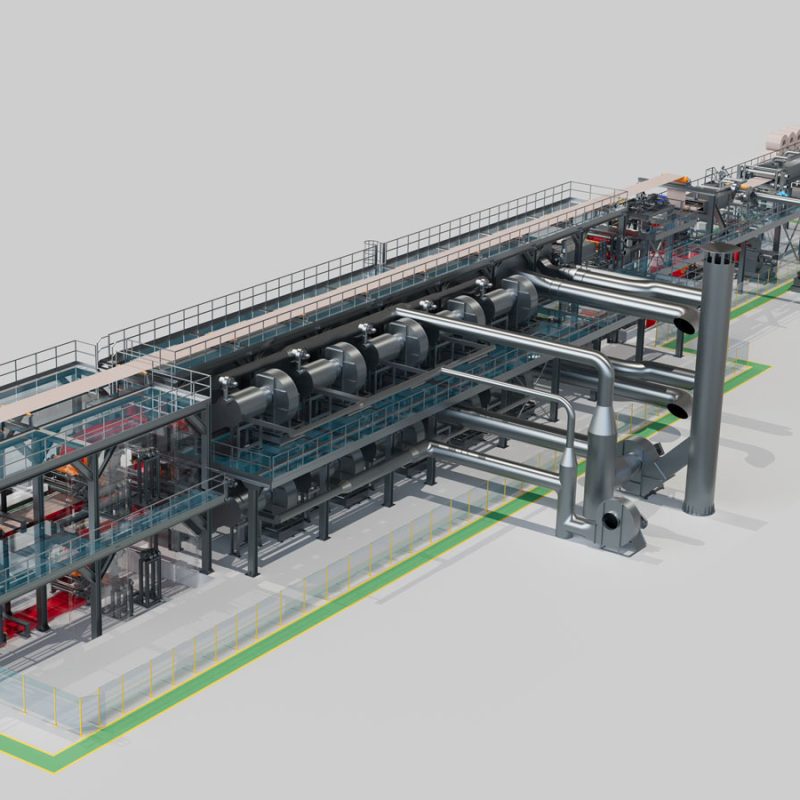

- One or more hot air polymerization units and water and/or air cooling system;

- Groups for the treatment of exhaust containing solvents coming from painting chambers and from polymerization ovens, using thermal or recuperative incinerators;

- Possible co-lamination groups the application of permanent decorated films;

- Possible decoration groups using inks with engraved rollers;

- Groups for temporary protective film application.

LCC Liquid Coil Coating Line it's a technological process used for the continuous painting using solvent-based liquid paints of cold-rolled and galvanized steel strips or aluminum and its alloys. The prepainted finished product guarantees adequate preparation for following process of blanking, bending, moulding and profiling.

The main fields of application are:

- window and door complements;

- false ceilings;

- foamed covers;

- foamed panels for partition;

- continuous building facades;

- rainwater drainage systems;

- packaging industry;

- appliance industry;

- transport industry;

- serigraphy.

Paints with different characteristics can

be applied, such as:

- polyester;

- polyurethane;

- epoxy;

- polyamides;

- fluorinated (PVDF);

- plastisol.